Horizontal spray coating

Flat spray application technique

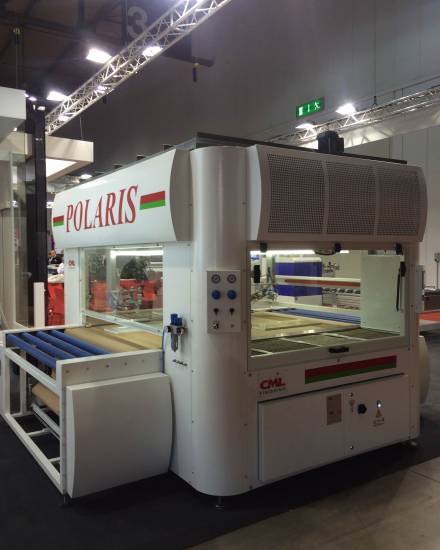

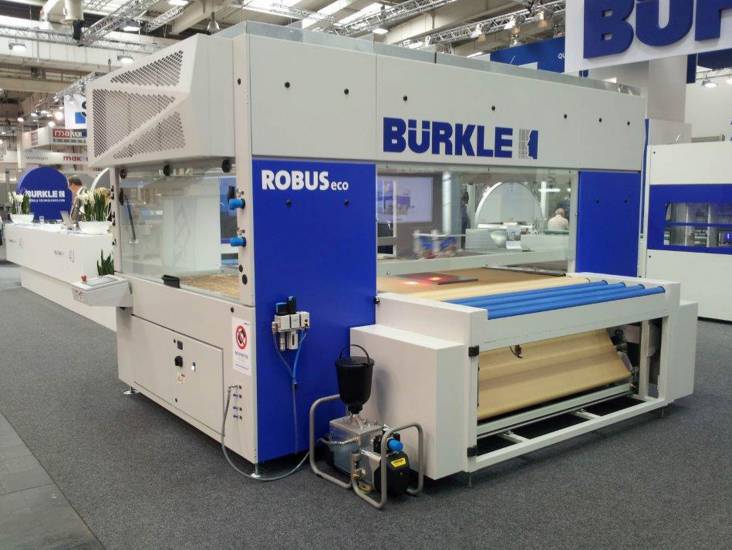

This is the application field where the synergy between CML Finishing and associate ROBERT BUERKLE GmbH is strongest.

Automatic spray coaters, whether they use reciprocating or rotary movement, represent the normal evolution of manual applications in spray booths, thanks to their extreme flexibility, the possibility of applying the coating product simultaneously on the top and edges of the panel and allowing the use of any type of paint, whether it is water or solvent-based.

The conveyor system can be a self-cleaning belt, either with the recovery of the excess paint that is not applied to the piece, or with disposable paper.

On the other hand, the solid particulate contained in the ejection air can be abated with dry filters or with a water system.

An extremely vast series of accessories that can be included in the flat spray application technique: multiple paint feed circuits, motorised head height adjustment, quick gun plate change with external machine washing, quick colour change, super air filtering systems etc. etc. All of these are available for customisation of the machine, thereby effectively adapting it to the specific needs of the customers and the result that they desire.

Of the flat spray application techniques, one uses the Controlled-axis Robot which represents the best that the market has to offer for customers looking for excellent application quality or who work with a type of product with particular aesthetic features and sizes.

The number of times that the spray guns go over the piece, or over the various areas of the piece (surface or edge) and the direction of application (lengthwise or crosswise or mixed) are programmable, thereby making it possible to obtain the desired finishing quality even on pieces that are particularly complicated, shape-wise.

The impregnation systems for example of beams or linear wood elements that use a gravity flow system called "flow-coating" complete the range of spray application techniques, used exclusively by the wood industry. Flow-coating works at very low pressures and with high amounts of applied product, specifically so that the wood absorbs the treatment products (fungicides or other)